The company's predecessor was Jingyue Valve Factory established in 2003, focusing on the production, R&D and design of stainless steel ball valves, stainless steel fire hydrants, booster valves. After more than ten years of development, the business needs of Jingyue Valve Factory have been increasing day by day. In order to meet market demand, Wenzhou Joepai Valve Co., Ltd. was established in 2020. The company's business scope has been expanded to the research, development, production, sales and service of gate valves, globe valves, check valves, butterfly valves, strainers, fully welded ball valves and fluorine-lined valve series, etc. We also focus on providing customized services to meet the unique needs of global customers for valves supply. Every process from design to delivery is carefully managed by industry experts to ensure seamless global distribution. We are always committed to innovation and continuously develop high-quality products while maintaining excellent cost performance. Since its establishment, the company has always adhered to the business philosophy of "survival by quality and development by technology", dedicated to shaping the image of Joepai and carefully cultivating the Joepai brand. After years of development and continuous learning from experience, it has established a good corporate image in the industry.

Wenzhou Joepai Valve Co., Ltd. is a collection of design, development, manufacturing and sales as one of the professional industrial flow control solutions enterprises, located in Zhejiang Province, Wenzhou Longwan District, near the airport, convenient transportation.The products are produced in accordance with international standards API, ANSI, JIS, ISO, DIN, GOST, BS and domestic standards JB, GB. With exquisite craftsmanship, superb technology, optimized sales concept and good reputation, they have won the praise of customers. The company also has CAD valve design, UG three-dimensional shaping and quality inspection test center. Powerful production equipment and perfect testing methods can effectively improve product quality and effectively protect the interests of customers. Welcome customers at home and abroad to cooperate sincerely and create brilliance together!

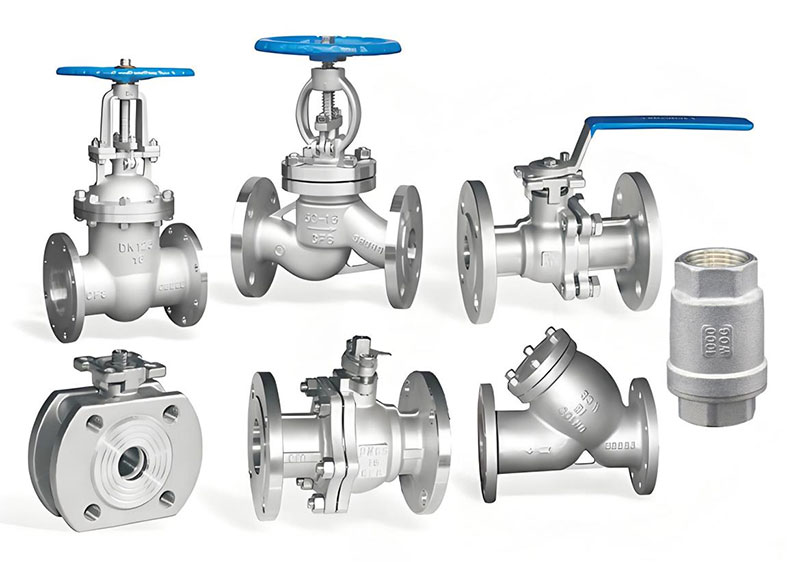

Ball Valves: Used in petroleum, chemical, and natural gas pipelines for shut-off and flow control, with high-pressure resistance. Fully Welded Ball Valves are ideal for buried pipelines or long-distance transportation due to superior sealing. Gate Valves and Globe Valves serve as shut-off devices, with the latter allowing flow regulation. Check Valves prevent backflow. Butterfly Valves manage large flow rates in water supply systems. Steam Traps remove condensate in steam systems. Safety Valves and Pressure Reducing Valves ensure pressure control and system protection. Brass Valves handle corrosive media, while Plunger Valves withstand high temperatures/pressures. Eccentric Semi-ball Valves suit particle-laden fluids; Knife Gate Valves handle viscous or solid-containing media. Ceramic and Fluorine-lined Valves resist corrosion/abrasion. Pinch Valves are used for slurries/powders. Filters purify media, while Fire Hydrants and Booster Valves are critical for firefighting water supply systems.

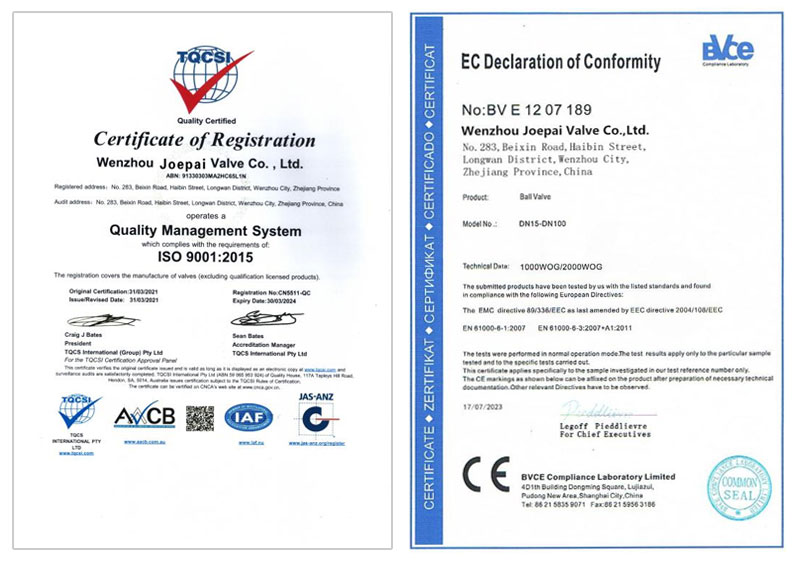

Our company has passed ISO 9001 quality management system certification to ensure standardized control of the entire process from R&D to production; our core products have obtained EU CE certification and meet international safety and environmental standards. In addition, the ball valves have passed the Korean KC certification and successfully obtained Korean market access qualifications, demonstrating the excellent competitiveness of the product in the Asia-Pacific region.

We have always been customer-oriented and established a complete quality assurance system. An independent quality inspection department has been established within the company, and all employees have passed strict QC training and certification to ensure that each batch of products has undergone multi-dimensional testing, providing high-standard pre-sales consultation and after-sales technical support services to global customers.

With more than ten years of deep cultivation in the field of fire protection equipment, our company has its own production base and core technology. Fire hydrant products have passed the Australian AS 2419.2-2009 certification, and the Dual Booster system complies with the AS 2419.3 technical specifications, fully meeting the stringent requirements of international fire safety. With our continuous innovative R&D capabilities, we provide efficient and reliable solutions for the industry.

The company is equipped with advanced production equipment and a complete testing system to fully guarantee the manufacturing accuracy and quality reliability of products. The specific configuration is as follows:

CNC lathes: more than 20 high-precision CNC lathes;

Machining center: 1 multifunctional machining center is equipped to meet

the integrated processing needs of complex structural parts;

Pressure test equipment: 2 special pressure test equipment are equipped.

The company has built a complete testing laboratory. The key equipment

includes:

Spectral quantitative analyzer, high-precision roundness tester, hardness

tester, torque wrench, valve fatigue tester

Through the combination of large-scale CNC equipment and full-process testing technology, the company has achieved full-chain quality control from raw material storage to finished product delivery, ensuring that the products meet international standards and customer customization needs, and providing solid guarantees for high-performance and high-durability products.

The company primarily focuses on international markets, with exports accounting for approximately 85% of total sales. Its products are distributed across diversified regions, demonstrating strong competitiveness and customer trust worldwide. Key market shares include:

Europe: 25%

Australia:20%

South Korea: 20%

Southeast Asia:10%

Middle East: 5%

North America :3%

South America :2%

Domestic & Others: 15%

As a high-tech enterprise that has been deeply involved in the valve manufacturing field for many years, we focus on providing customers with standard and customized valve products, covering all categories such as gate valves, ball valves, butterfly valves, and stop valves. We always take "precision customization and quality escort" as the core of our service, and ensure worry-free cooperation with customers through a full-process service system.

Demand In-depth Docking: The technical team provides 1-to-1 solution design support, and can carry out personalized development based on your working parameters (pressure/temperature/medium, etc.), design drawings or samples to ensure that the product meets international standards such as API and ANSI.

Digital production line: Using CNC precision machining center and

automated assembly system, the error accuracy of key components is

≤0.01mm.

Five-level quality inspection system: from raw material spectrum detection

→ casting X-ray flaw detection → assembly air tightness test →

high-pressure water pressure test (1.5 times rated pressure) → final

inspection before delivery, the whole process is traceable.

12-month warranty: From the date of delivery, the product will be repaired/replaced free of charge for quality issues not caused by human factors.